The boiler is a fantastic appliance in any home, commercial or industrial space. It keeps you warm, supplying heating and hot water in the coldest times of the year. So, you know of a boiler, but are you familiar with a boiler flue? If so, are you sure your knowledge of its regulations is sufficient?

Whether you’re a professional installer or homeowner looking to upgrade your system, it’s worth knowing your stuff about boiler flues. They play a vital role in how gases leave your boiler, so they require thorough consideration.

In this guide, we’ll delve into what a boiler flue is and how you can make sure you have an authentic system for your property. For in-depth and government guidance, refer to Approved Document J for the latest regulations.

Table of contents

- What is a boiler flue?

- What comes out of a boiler flue?

- What are the different boiler flue types?

- Are there any commercial boiler flue regulations?

- The Clean Air Act

- Where should a boiler flue be placed?

What is a boiler flue?

The boiler flue (a type of pipe) helps carry exhaust gases (products of combustion) away from the boiler and moves them outside to release into the atmosphere. Which one you choose will depend on what application you will use the flue on, and the fuel being used by the boiler.

What comes out of a boiler flue?

You may have heard of combustion products, but did you know different boiler flues expel these differently depending on design?

What comes out of a condensing boiler flue?

The short answer is combustion by-products created while using the device. The main types of gases expelled are as follows:

- Carbon dioxide (CO2)

- Water vapour

There are other gases like NOx, but the two above are the most focused gases you must check for safety.

Looking closer at water vapour, this type of product in exhaust gases needs to condense into a liquid form and then get removed from the flue. The temperature of the exhaust gases within the flue needs to be reduced to meet that level.

The boiler will release condensed, cooled gases via the flue. The quality of the fuel burned, and the boiler efficiency, may result in the flue expelling minor traces of combustion by-products.

What are the different boiler flue types?

There are many types of boiler flue. The most common being balanced flues, open flues and fan flues. If you’re confused, don’t worry, we’ll help you out.

We’ve presented this information as briefly as possible. With this in mind, it’s vital you check out Approved Document J as this document will define the different flue types in more detail.

Balanced flues

A balanced flue is a type of closed system – flues with two pipes. One pipe is for air supply, while the other is to expel products of combustion.

Oxygen is pulled into the boiler from the outside, easing combustion using natural draught created by the flue gases before the exhaust expels through an external wall.

It’s worth noting these are preferable for combi boilers as this type of boiler is normally room-sealed.

Open flues

The tube removes by-products of combustion away from the boiler through an external wall via a draught diverter. The draught diverter pulls air through the flue, where the combustion air supply is drawn directly from the boiler’s surroundings (not fresh outside air).

With this flue, you must have suitable ventilation around the boiler for sufficient airflow.

Fan flues

These work similarly to the balanced flue but use a fan to power air into the boiler. The fan also powers the removal of waste gases.

This particular system enables longer flue runs because the air and waste gases can be sent further distances.

What are the commercial boiler flue regulations?

Under Approved Document J, a boiler is considered a ‘combustion appliance’ because it generates heat for space heating and water heating.

Regulations are defined thoroughly in Approved Document J, but here is a summary of what your flue must have to meet current standards.

Make sure the flue has a CE Mark

The point of a CE Mark will be to specify the limits of the product, specifically operational and performance. It will also meet the legislative requirements of the EEA (European Environment Agency).

Temperature rating must be identified

This will specify what minimum temperature the flue can last at for continuous use. The BFCMA (British Flue and Chimney Manufacturer’s Association) says the minimums are as follows:

- T400 for multi-fuel

- T200 for gas and oil

As indicated via Approved Document J, here is a full list of temperature classes for flues.

| Temperature class | Nominal working temperature (less than or equal to) Celsius |

| T 080 | ≤ 80 |

| T 100 | ≤ 100 |

| T 120 | ≤ 120 |

| T 140 | ≤ 140 |

| T 160 | ≤ 160 |

| T 200 | ≤ 200 |

| T 250 | ≤ 250 |

| T 300 | ≤ 300 |

| T 400 | ≤ 400 |

| T 450 | ≤ 450 |

| T 600 | ≤ 600 |

Pressure rating is also required

These ratings are identified as follows:

- N = Negative pressure applications

- P = Positive pressure applications

- H = High positive pressure applications

After these letters will either be ‘1’ or ‘2’. Below is a table showing current pressure classes. You can find out more about these ratings via Approved Document J.

| Pressure class | Test pressure (PA) | Gas tightness (Max. leakage rate L/s/m2) |

| N1 | 40 | 2.0 |

| N2 | 20 | 3.0 |

| P1 | 200 | 0.006 |

| P2 | 200 | 0.120 |

| H1 | 5000 | 0.006 |

| H2 | 5000 | 0.120 |

Condensate resistance is vital

Condensates must be able to flow freely through the flue to the drain in any commercial boiler system. This means it should be suitable for wet or dry operation. More specifically:

Wet (W): It must have the ability to hold condensate within the flue.

Dry (D): It must have the ability to work under dry conditions, meaning the flue gas temperature is high enough to prevent condensation from forming.

E.g., D3 means the flue is resistant to products of combustion from burning wood in dry conditions.

Numbers after the W or D assigned letter are defined in the table below (via BS EN 1443-2003 found in BS EN 1443-2019). More information can be found via Approved Document J.

| Corrosion resistance class | 1 (Possible fuel types) | 2 (Possible fuel types) | 3 (Possible fuel types) |

| Gas | Gas: sulphur-content ≤ 50 mg/m Natural gas L + H | Gas Natural gas L + H | Gas Natural gas L + H |

| Liquid | Oil: sulphur-content ≤ 0.2 mass % kerosene: sulphur-content ≥ 50 mg/m3 | Oil: sulphur-content ≤ 0.2 mass % kerosene: sulphur-content ≥ 50 mg/m3 |

|

| Wood | Wood in open fireplaces | Wood in open fireplaces Wood in closed stoves |

|

| Coal | Coal | ||

| Peat | Peat |

Corrosion resistance is not something to be forgotten

The type of fuel used will affect the resistance required for the flue to prevent it from wearing away from products of combustion. More specifically:

| Type of resistance | Description of resistance |

| V1 | •Attack from products of combustion from gas. |

| V2 | •Attack from products of combustion from light oil (sulphur content up to 0.2%). •Attack from products of combustion from natural wood. •If the flue passes the V2 wet test, the flue is assumed to comply with D3 under dry conditions). |

| V3 | •Attack from products of combustion from heavy oil (sulphur content > 0.2%). •Attack from products of combustion from solid fuels. •Attack from products of combustion from peat. |

| VM | •Not tested (Rating declared by manufacturer). |

Keep in mind liner material specification

As with the corrosive requirements, the flue liner must also be able to last against corrosive effects. This includes those from the fuel used for the system and during condensation.

The two types of flue liners are as follows:

- Single skin liners: Suitable for gas appliances.

- Twin skin liners: Suitable for wood and multi-fuel appliances.

The twin skin liners are manufactured from overlapping strips of high-grade stainless steel for a smooth sealed flue way.

Never use single skin liners with wood or multi-fuel applications.

Note: Components used with a flexible liner must also have UKCA/CE Approval to certify as a system chimney.

A must-know: Soot fire resistance and the distance to combustibles

Soot fires mean you must ensure the flue is resistant to such events and put it at a distance that is safely away from materials that would burn under heat, such as timber frames.

The above is often expressed as G for soot fire resistance or O for not. This is followed by a declaration of minimum distance to combustibles (noted in mm).

If the G classification is there, this means the product has remained intact after testing at 1000℃ for 30 minutes. Combustible material temperatures, at the designated distance, must not exceed 100℃ at an ambient temperature of 20℃.

Distance to combustibles (for connecting flue pipe)

When it comes to distance to combustibles for connecting flue pipe tested to BS EN 1856-2, these will typically have another classification:

- M (Measured)

- NM (Not Measured)

If NM, the minimum distance to combustibles must be three times the internal diameter of the connecting flue pipe. That is unless said pipe has the BS EN 1856-1 standard, where distance to combustibles will be defined by the manufacturer.

If a system chimney is approved to EN 1856-1 (used as a connecting flue pipe), the distance to combustibles required will again be defined by the manufacturer’s declaration.

Choose one with a straight chimney

A flue with bends leads to poor performance. If your boiler runs on natural gas, a vertical rise of 600mm is the minimum recommended for the immediate exit of these gases from the boiler before the directional change.

In Approved Document J it states, for bends in flues, an “angle should not be more than 45°” and “90° bends are not suitable for solid fuel appliances”.

Cleaning and maintenance are key

Regular cleaning and maintenance make for a safer and more efficient system. So, when first fitting your boiler, ensure any sections with a change in direction are easy to access. This is possible by using swept elbows, which act as a collective spot for debris. Couple this with an inspection point to avoid the need for taking the system apart completely during cleaning.

When performing inspections, you or the hired engineer must be Gas Safe registered to ensure all regulations and repairs are suitable.

The danger of unsafe maintenance, cleaning and poor repairs has high safety risks, including carbon monoxide poisoning. This condition can be fatal, so ensure the installation is properly carried out.

Support is always appreciated

The flue must have the correct support to ensure easy access for inspection and testing. This involves positioning the joints to allow for such measures to occur, with test points along the flue’s length for combustion and leakage testing.

The Clean Air Act

Another consideration and required regulation to act on relates to the Clean Air Act.

First looked at in 1956, with later amendments and the focus on the act’s enforcement in 1993, means the flue must reach a required discharge height. This discharge height is enforced to prevent harmful emissions and avert health risks to the public.

How is this calculated? It’s simple – note the fuel type burned and the maximum rated output of the appliance.

Where should a boiler flue be placed?

As we’ve already mentioned, regulations are in place for boiler flues, which include where to install the flue. It protects those living or working within the property, in addition to neighbouring persons, from extracted boiler gas re-entry into the property or neighbouring buildings.

The primary position for a flue is horizontal, with direct attachment to the boiler, leading to the outside via an external wall.

Depending on the situation, some flues can fit vertically or in a different location than external walls. However, other rules are in place for this type of fitting.

You may also not need a flue, but this will only be possible if you have an old-fashioned back boiler. With that said, these are being phased out because of safety concerns and a lack of available parts, especially since the decision to stop these models in recent years.

How far should the boiler flue be from the window?

The minimum distance your boiler flue should be away from the window is 200mm, which includes any windows that can open and air vents in the vicinity.

VELUX windows have a specific regulation saying the placement of the boiler flue must be at a minimum distance of 2,000mm below this style of window.

For doors, the distance of the flue should be a minimum of 1,200mm away from it.

A final note on this is the size of the boiler will typically dictate how far you need the flue from the windows, doors and air vents. These are, however, minimum distances to follow, and if more space is available, use this for the design of the heating system.

Additionally, you can check out NHBC for the latest standards about flues and more when it comes to boilers and heating requirements.

How far does a boiler flue have to be from a neighbour’s property or local feature?

The minimum distance of a boiler flue should be 600mm. As a minimum, this should ensure a sufficient distance from the following:

- Opposite walls

- Buildings

- Fences

As for height, if your boiler flue faces a public space (e.g., pavement), it must be installed 2000mm off ground level as a minimum. With that said, the maximum height of boiler flues in general will depend on the instructions from the manufacturer. You must not exceed the flue length designed for the boiler.

If two flues face each other and both properties own the boundary for a property, they must be 1,200mm apart.

Again, these are safety measures to keep you and the public safe from toxic gases. However, property location can affect distances and heights. So, speaking to a qualified engineer or officials responsible for building control in the area is recommended to check what regulations apply.

Additional regulations for boiler flues

Other, less-known regulations that are vital for the performance and safety of the boiler flue include its fix, sealing, the angle of the flue and protection covers.

With regards to the fixing of a boiler flue, this must be sufficient with seals on both sides of the wall to prevent emissions from returning into the property via gaps that could be around the flue.

For the angle of the flue, you must ensure it is installed so that water or chemical droplets forming within the pipe do not drip back into the boiler.

To ensure the flue works sufficiently, you must install it at an angle that prevents water or chemical droplets forming inside the pipe from dripping back into the boiler.

For boiler flues installed or in the process of being installed on a ground floor wall, you must install a protective cover over it. This could be a grill or metal box.

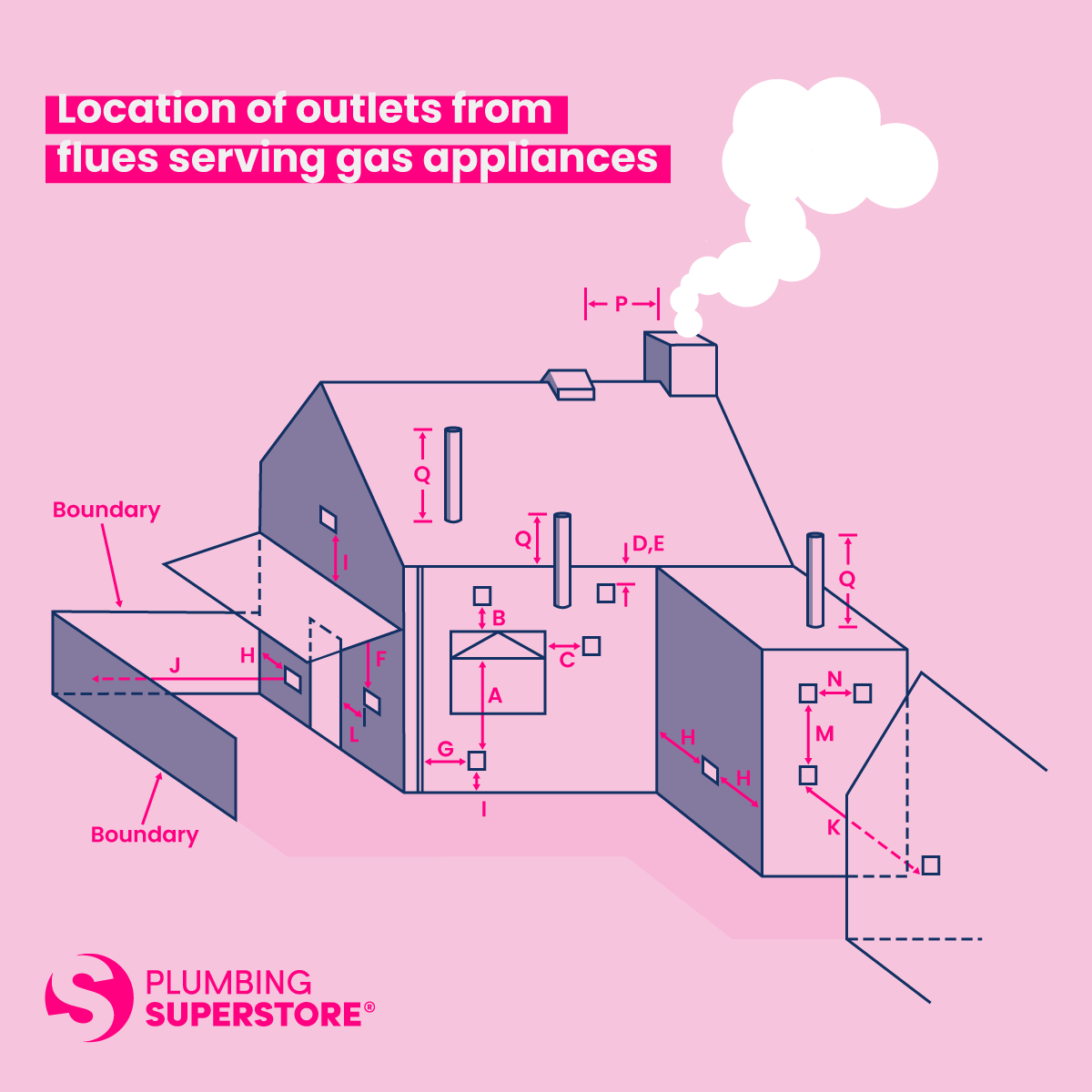

As expressed in Approved Document J, here is a diagram of the positioning of outlets from flues that serve gas appliances (with rated input up to 70kW (net). The relevant table can be found underneath the diagram

Please note: This is only one of many flue reference diagrams and a brief overview of the placements via the table. For all relevant flue information, you must refer to the latest regulations.

| Letter | Location | Additional information |

| (A) | Below an opening (1) | (1) Opening includes openable elements like openable windows, or fixed openings such as air vents. In addition, the outlet should not be nearer than 150mm (fanned draught) or 300mm (natural draught to an opening in to a building fabric formed for the purpose of accommodating a built-in element, such as a window frame. |

| (B) | Above an opening (1) | |

| (C) | Horizontally to an opening (1) | |

| (D) | Below gutters, soil pipes or drainpipes | |

| (E) | Below eaves | |

| (F) | Below balcony or car port roof | |

| (G) | From a vertical drainpipe or soil pipe | |

| (H) | From an internal or external corner or to a boundary alongside the terminal (2) | (2) Boundry (defined in paragraph 0.4 (4) of Approved Document J). Smaller separations to the boundary may be acceptable for appliances that have been shown to operate safely with such separations from surfaces adjacent to or opposite the flue outlet. |

| (I) | Above ground, roof or balcony level | |

| (J) | From a surface or a boundary facing the terminal (2) | (2) Boundry (defined in paragraph 0.4 (4) of Approved Document J). Smaller separations to the boundary may be acceptable for appliances that have been shown to operate safely with such separations from surfaces adjacent to or opposite the flue outlet. |

| (K) | From a terminal facing the terminal | |

| (L) | From an opening in the car port into the building | |

| (M) | Vertically from a terminal on the same wall | |

| (N) | Horizontally from a terminal on the same wall | |

| (P) | From a structure on the roof | |

| (Q) | Above the highest point of intersection with the roof | |

| (P) | From a structure on the roof | |

| (Q) | Above the highest point of intersection with the roof |

With all the above information about regulations, the most important thing to do here is to ensure your installer is qualified and to follow manufacturer instructions diligently when installing the flue and the boiler.

If you are unsure whether your existing boiler meets regulations, contact a qualified engineer or local authority to review the state of your boiler and recommend your next steps.

With all this information in hand, do you know what boiler you want? Check out our boiler buyer’s guide, as well as our dedicated guide to commercial boilers and more Help and Advice to ensure you have the right appliance for your requirements.