You may hear “boiler” and immediately know what one is – or so you think. Your first instinct about a boiler may be correct, that is, for a domestic boiler, but commercial boilers are a whole different matter.

Wait, what’s the difference between a commercial and a domestic boiler? Well, we’ll explain right here in this guide. We’ll go through the features of a commercial boiler, its similarities with the domestic boiler and much more.

By the end, we’re confident you’ll know why the distinction matters and feel well-informed about approaching a commercial boiler purchase.

Table of contents

- The big question – what is a commercial boiler?

- Commercial boiler installation – where to start!

- Are there any commercial boiler flue regulations?

- Types of commercial boilers explained

The big question – what is a commercial boiler?

We’ll start with this one since we explain general domestic boilers via our buyer’s guide. Did you know we had a buyer’s guide for boilers? Anyway, onto commercial boilers!

A commercial boiler typically has two defining features. The first is its function as a heating and hot water supplier to non-domestic buildings. The second is that it is a pressurised system that burns fuel or uses electricity to produce hot water or steam.

Commercial boilers can also be mounted on the wall for convenience, but come with parts that separate them from domestic-style boilers, including (not limited to):

- Low loss headers

- Compensated mixing circuits

- Flue fan dilution systems

They also have an increased flow rate. This is made possible due to the heat exchanges being of a larger size. This enables more radiators to be installed in the heating system without compromising its circulation.

How does a commercial boiler work?

The hot water or steam molecules produced by the system circulate through the building via pipes, creating a cosy, heated environment for people within the building.

Fixtures serviced by the boiler’s hot water typically include:

Commercial boilers often use natural gas as the primary fuel source for heat generation, but fuel oil or electricity-resistant coils are optional for generating heat.

When does a boiler become commercial?

The primary factor affecting this decision is size. Its size (output) is measured in kW (kilowatts).

Domestic boilers often have a smaller output than commercial boilers. In most cases, domestic boilers vary between the 24kw and 42kw range but have the potential to be up to 70kW – anything beyond this is labelled as commercial.

Commercial boilers are suitable for larger premises, including:

- Warehouses

- Factories

- Offices

- Leasure centres

- Colleges

- Health clinics

- Workshops

- Hotels

- Care homes

- Schools

- Hospitals

Essentially, any type of building that isn’t domestic is better suited to a commercial boiler, especially when gas and oil-fired commercial boilers have an impressive output ranging between 200kW to 1,500kW.

With that said, the sizing range isn’t straightforward, as some commercial boilers have under 70kW output. Some portable electrical boilers, for example, have an output ranging from 15kW to 36kW.

You can utilise these portable boilers in smaller commercial settings, such as:

- Construction sites

- Shops

- Garages

- Sports halls

You can also use them to aid plaster and screed drying processes during projects of a larger size.

Commercial boiler installation – where to start!

There are so many commercial boilers to choose from that it can be quite challenging to choose the right one for our property. Luckily, you can minimise these options by looking at specific features.

Look at the commercial boiler size

The size of your boiler will matter because of the standards and requirements for your property. Your first port of call will be to know these conditions required for heating and hot water. Have answers to these questions:

- How large is the building?

- How many radiators need to be heated?

- How many water outlets does the property have?

Is the building well-insulated already? (e.g., double glazing and spray foam insulation)

If you’re unsure, you can request a professional to survey the site and help you choose a boiler with a suitable technical output for the property.

Once you know the answers to these questions, you can find a boiler with the right output. It’s also worth knowing older buildings are less likely to have adequate insulation than new buildings. Moreover, if there is a workshop with fibreglass roofing, heat is likely to escape more quickly than through roofs or ceilings with tiling.

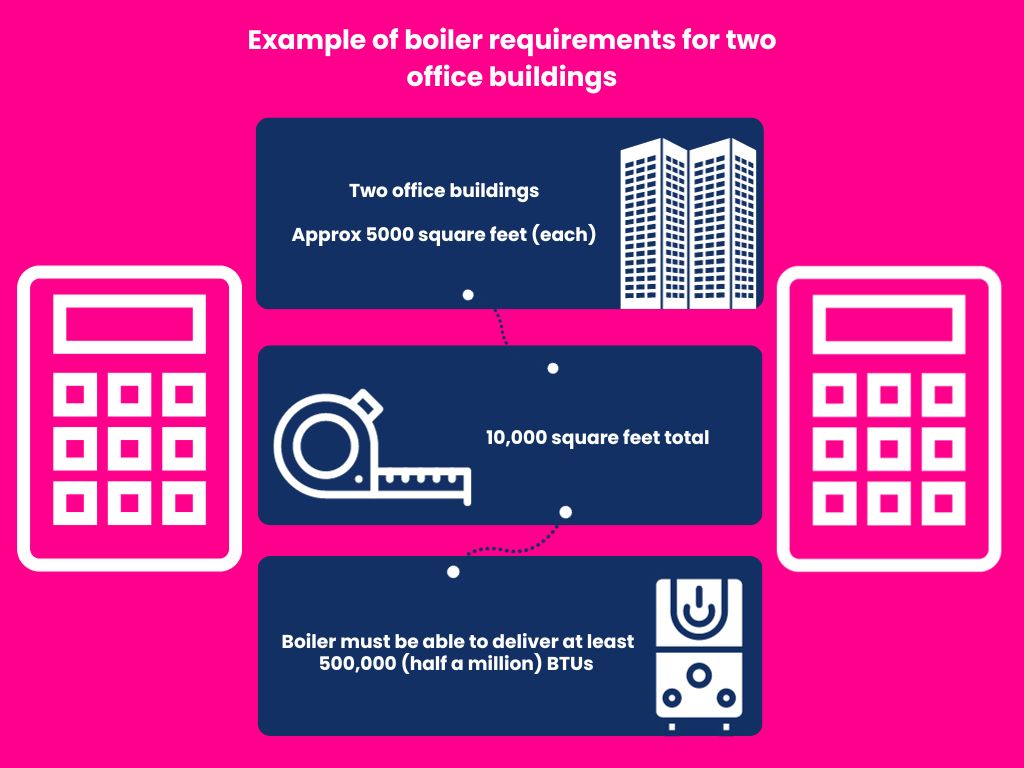

Tip: For each square foot of space you want to be heated, equate this to about 50 BTUs (British Thermal Units).

It is also recommended commercial boilers have a minimum of 300,000 BTUs per hour. Any less falls under domestic.

Choose a suitable fuel type for your boiler

The three most popular fuels for commercial boilers are:

- Natural gas

- Fuel oil

- Electricity

Other options are available but aren’t as common. This includes HVO (hydrotreated vegetable oil), a type of renewable diesel and an alternative to traditional heating oil. Its popularity has grown because it is more environmentally friendly than other fuels. It also has more sustainability and efficiency without sacrificing high levels of performance.

Do you want a boiler that’s energy efficient?

We all know heating and hot water can contribute to property bills. To combat this, look for something to help you support energy efficiency.

You won’t have to look far as there’s plenty available nowadays – but don’t just run for the first you see. Look at the quality of energy efficiency information about the boiler.

You’ll also need to factor in size. Why? Well, too much unnecessary capacity could lead to higher fuel costs than intended.

Current regulations must be considered during this stage as there are minimum standards when it comes to efficiencies for gas-fired heating systems in existing dwellings. These are clarified via Approved Documents, so ensure to check the current standards to ensure efficiency requirements are met.

If you’re unsure whether your chosen boiler is efficient, find out what efficiency rating your boiler is via our guide to boiler efficiency ratings.

While you’re at it, check out our 10 energy saving tips to help you with your energy bills!

Ensure your supplier can support and maintain the boiler

Good supply leads to better help, which means looking for a distributor to help you with upkeeping your boiler after they’ve delivered.

Look at the company policies to find out what they can help with. Here are some questions to get you started:

- Do they offer free replacements?

- Are they able to perform minor repairs?

- Is their company able to check your boiler performance?

These are just some questions you could ask before choosing your desired boiler. Read their policy thoroughly to ensure the results of their help are satisfactory and suitable for your budget.

Who can install a commercial boiler?

If your commercial boiler is connected to the same heating system and with an output of 70kW, the engineer must be qualified with a commercial gas qualification. The engineer must also have a full domestic qualification or certification to work with domestic gas appliances under 70 kW.

Are there any commercial boiler flue regulations?

Under Approved Document J, a boiler is considered a ‘combustion appliance’ because it generates heat for space heating and water heating.

The flue (a type of pipe) helps carry exhaust gases (products of combustion) away from the boiler and moves them outside to release into the atmosphere. Which one you choose will depend on what application you will use the flue on, and the fuel being used by the boiler.

Regulations are defined thoroughly in Approved Document J.

Types of commercial boilers explained

Commercial boilers aren’t a one-size-fits-all. Now, we already know that boilers can burn different fuel types, but what are the exact types of commercial boilers and why are they different? Well, let’s take a look.

Below is a brief overview, but you can find out more in our boiler buyer’s guide to ensure you have full knowledge of the different boilers available for your requirements.

Firetube boilers

A firetube boiler probably sounds epic with the word fire in the title. Let’s dive in to find out more about it.

How does it work? Hot gases from combustion flow through tubes, transferring heat into the water sitting in the pressure vessel.

Where is it installed? Smaller industrial areas where they work at a lower pressure.

What makes it special? The firetube boiler is cost-effective because it uses a simple design requiring very little maintenance compared to something like a watertube boiler.

What does it look like? Designs are varied, but at this moment, you’re likely to find one with large furnace tubes. These tubes are where the flame of combustion is supported.

On each end of the boiler, you’ll find a door which might be usable as turnarounds. This redirects flow gases, allowing other passes through the pressure vessel.

The turnaround is important, as it affects which class your boiler belongs to. These classes are as follows:

- Dry back – Using refractory

- Wet back – Using water surrounding the rear wall

- Semi-wet back – Combination of the above

This type of boiler is also classed by how many passes the hot gasses make, specifically through the water in the pressure vessel shell. A ‘pass’ is assigned for every set of tubes the flue gas travels through. The most common of these passes are two, three and four-pass designs.

Each type has benefits and setbacks, so here’s a small tip to help you out: The more passes your boiler has, the more efficient it is and the higher the extraction rate.

Watertube boilers

Watertube boilers might sound futuristic, but it’s very much in use today. So, let’s look closer at this different type of boiler.

How does it work? Hot gases from combustion flow between tubes filled with water, circulating while an external fire source heats the liquid.

Where is it installed? Power generation plants commonly use these types of boilers. This is because the steam produced by the system powers turbines and generates electricity.

What makes it special? The watertube boiler works at a bigger capacity, meaning it can handle larger pressures and exceptionally high temperatures compared to something like a firetube boiler.

What does it look like? The design features two (sometimes more) drums titled ‘mud drum’ and ‘steam drum’. These drums have bent tubes, purposefully designed that way, for water transfer between each drum.

Watertube boiler designs vary depending on how the mud drums and steam drums are arranged, as such, here is a brief overview of the different types below:

| Type of watertube boiler | Design |

| A type | Two mud drums are near the outside walls, with one centrally found steam drum and burner located on the centreline of the steam drum. |

| O type | One centrally found mud drum and steam drum featuring bent types on each side with the burner located on the centreline of each drum. |

| D type | One mud drum and steam drum and located on the left or right side of the boiler, while a large bent tub arrangement with the burner sits out to the side and away from the drums' centrelines. |

| Flexible (Similar to O type) | A more intricate tube bend arrangement enables a more space-efficient design, creating multiple passes for flue gas flow, and enhancing resistance to thermal shock. |

A more intricate tube bend arrangement enables a more space-efficient design, creating multiple passes for flue gas flow, and enhancing resistance to thermal shock.

Commercial electric boilers

Well, this one couldn’t be simpler with its title, but why stop with just that? Let’s look closer at this type of boiler.

How does it work? You might have already figured it out, but if not, this type of boiler uses electrical energy without the use of combustion energy transferring into the water.

Where is it installed? Their size makes them an ideal fit for most areas of the property. Whether it’s a cupboard, a kitchen or something more discrete, it will be a great modern asset for any location.

What makes it special? These types of boilers have an extremely high turndown. They also produce zero emissions and resistance to thermal shock.

What does it look like? Many of these boilers have a design that uses vertical and horizontal boiler shell orientation. Depending on who manufactured it, the construction of the boiler will affect whether they are for steam or hot water applications.

Condensing boilers

These boilers are much-loved by the modern market, but why is that? Well, let’s take a look.

How does it work? A condensing boiler has a heat exchanger that is manufactured to lower the temperature of the flue gas. This helps condense and capture extra energy from condensation. Now, if using steam, the boiler may have a condensing economiser to obtain the same energy from flue gas. The issue with this, however, is they can’t benefit from the design because of the variation between boiler water temperature and boiler exhaust dew point.

Where are they installed? Commercial and residential spaces both admire the condensing boiler for its many benefits, leading it to become one of the most popular choices in homes and small commercial applications.

What makes it special? Condensing hot water boilers are especially fancy because they are manufactured specifically to withstand high efficiencies impossible with your typical boiler. This could be 90% or higher, depending on design.

What does it look like? The primary shape of a condensing boiler is a rectangular box shape. With that said, due to their wide use across residential and commercial properties, they come in various sizes.

Vertical boilers

With a name like vertical boilers, it doesn’t leave much to the imagination. So, let’s take a look to find out why it’s unique.

How does it work? Despite their split from other boilers, they work similarly to a watertube boiler or firetube boiler, depending on the type you have chosen for the property.

Where are they installed? These are common where length and width restrictions prevent a typical horizontal boiler installation.

What makes it special? If you’re environmentally conscious, this one is ideal as it contributes less to your carbon footprint.

What does it look like? As expected, these are vertical but include tubed or tubeless designs depending on the performance requirements.

With all this information to hand, head on over to our other Help and Advice if you have other plumbing enquiries or visit our range to discover various boilers, boiler flues and so much more.