There are many jargon terms for pipe sizes in the UK, which can make getting the right pipe size for your next project quite tricky. With all those abbreviations, like OD, DN, and BSPT, it can be a real head-scratcher.

This can be especially difficult to navigate because UK and European terms like ‘nominal diameter’ are often used alongside North American ones like ‘nominal bore’. So, what terms do you need to know to determine pipe size?

That’s a question regularly asked by many of our customers at Plumbing Superstore and is why we decided to put together a comprehensive guide to pipe size terminology. So, without further ado, let’s dive right in.

Table of contents:

- Length

- Outside Diameter

- Inside Diameter

- Nominal Diameter

- British Standard Pipe

- Nominal Pipe Size

- How to measure pipe diameter

- Understanding pipe size terminology

Length

One of the more straightforward terms, ‘length’ or ‘pipe length’, refers to the physical measurement of the length of a pipe. This is typically done in metres.

It is essential that you know the exact pipe length for the following:

- Installation

- Maintenance

- Repairs

- Regulation compliance

- Flow efficiency

Outside Diameter (OD)

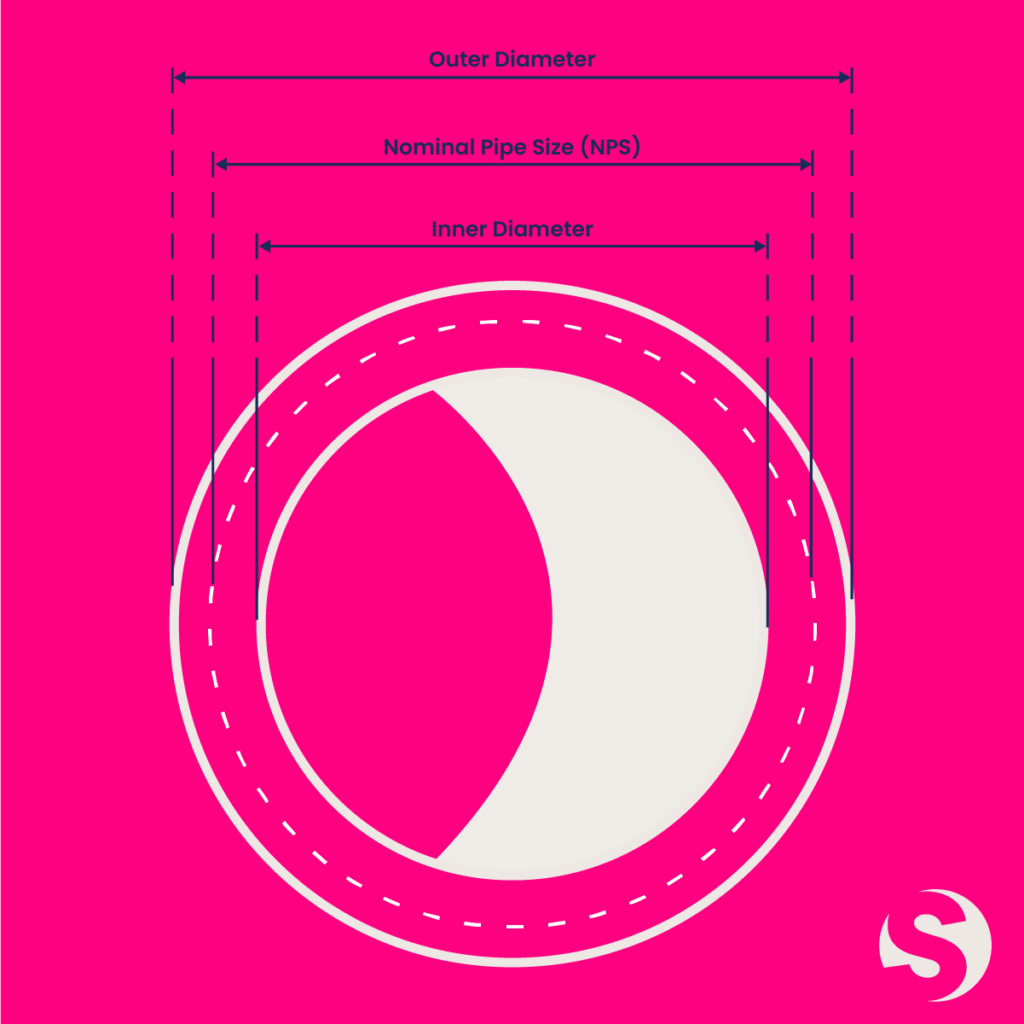

If you know the term ‘outer diameter’, you will know ‘outside diameter’ (OD). This refers to the measurements of the outer or external surface of a cylindrical pipe. In simple terms, it is the distance across the widest point of the pipe, passing through the centre.

Outside diameter determines the size and compatibility of the pipes and their associated fittings, connectors and components across various plumbing applications.

Inside Diameter

If you’re familiar with the term ‘inner diameter,’ you will know ‘inside diameter’ (ID). This is the measurement of the diameter of the hollow, cylindrical space inside the pipe. In simple terms, it is the distance across the widest point of the interior opening of the pipe, often measured from one inner edge to the opposite inner edge.

Knowing the inside diameter is essential for the following reasons:

- Flow capacity

- Fitting compatibility

- Material and thickness

Nominal Diameter (DN)

Nominal diameter is a typical term used to specify the size of pipes and pipe fittings in the UK and Europe. It is actually often abbreviated to DN from the French term diamètre nominal.

DN is based on the metric system, using millimetres to denote pipe sizes. This provides a consistent identity to the size of pipes and components.

In the DN system, the nominal diameter of the pipe is equal to the approximate inside diameter (ID) of the pipe in millimetres. Here are two common DN pipe sizes as an example:

- DN25 = A pipe with an approximate inside diameter of 25mm.

- DN50 = A pipe with an approximate inside diameter of 50mm.

The DN system simplifies pipe sizing and compatibility. It allows for a standardised and precise way to specify and select pipes and fittings, ensuring that components from different manufacturers and sources can be reliably interconnected.

British Standard Pipe (BSP)

British Standard Pipe (BSP) is a set of technical standards used for pipe threads and fittings in the UK and many other countries, particularly those in the Commonwealth of Nations. The BSP system is widely used in plumbing, hydraulics and various fluid transport systems. It provides a standardised way to connect and seal pipes and fittings.

Within the system, there are two common BSP thread options:

- Parallel threads

- Taper threads.

So, what sets them apart?

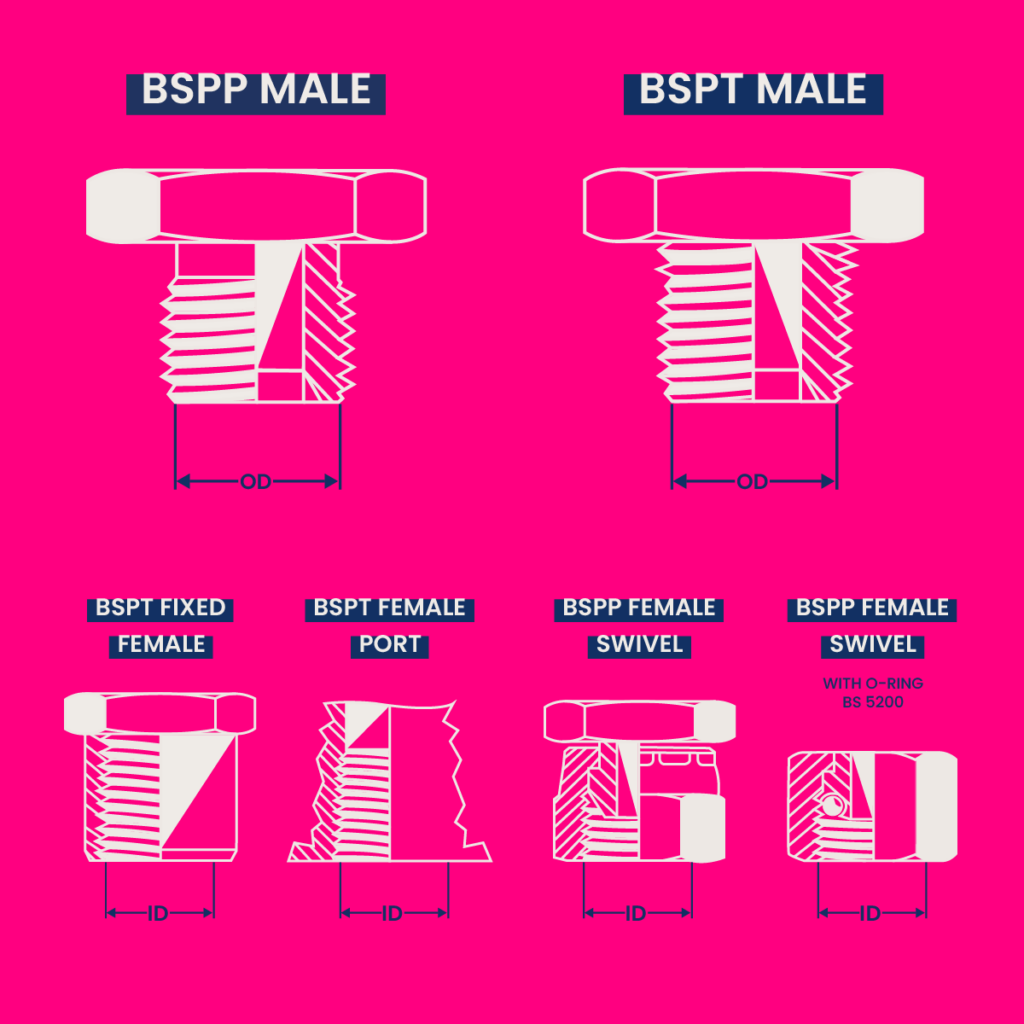

British Standard Pipe Taper (BSPT) threads

British Standard Pipe Taper threads have a taper or cone shape with a taper of 1 in 16. The angle of the taper is 55°. Designed to create a tight seal when engaged, they rely on the tapered threads to form a pressure-tight joint.

As the threads are tightened, they compress and create a seal, making BSPT suitable for applications where a pressure-tight joint is essential, such as water and gas plumbing.

British Standard Pipe Parallel (BSPP) threads

British Standard Pipe Parallel threads have a parallel thread design, which means the threads maintain a consistent diameter throughout their length. The thread angle is 55°, the same as in BSPT threads. They’re often used in conjunction with O-rings or gaskets to create a reliable seal.

BSPP threads are suitable for applications where a pressure-tight connection is not necessary but where a secure and leak-resistant connection is required. You commonly find them in hydraulic and pneumatic systems.

Are there similarities between BSPT and BSPP threads?

Yes. Both BSPT and BSPP threads can be combined to create two types of joints:

Jointing threads

These are designed to create a seal when engaged. BSPT threads can create a seal through the tapered threads, which tighten and compress when threaded into a mating component. In turn, BSPP threads create a seal by using O-rings, gaskets or other sealing components in combination with the parallel threads.

Long screw threads

With a longer engagement length, these threads are often found on bolts, screws or threaded rods. They serve applications that require a strong, secure connection.

Nominal Pipe Size (NPS)

Nominal Pipe Size (NPS) is a standardised system used primarily in North America to designate the approximate size of a pipe or pipe fittings. It’s an important part of the ASME B36.10M and ASME B36.19M standards, which are widely followed in the US.

NPS uses a nominal size (often referred to as ‘nominal bore’ or NB for short, usually expressed as a whole number) to describe the approximate inside diameter of a pipe.

Now, here’s where things can get a bit complicated. This nominal size is actually unrelated to the actual dimensions or measurements of the pipe. Instead, it’s the ‘approximate’ internal diameter of the pipe. While you may see DN and NPS used interchangeably, it’s absolutely crucial to point out that they are not the same!

Moreover, NPS specifications do not cover metric pipes. So, when you’re unsure which standard the product specifications use, always double- or triple-check with the manufacturer.

How to measure pipe diameter

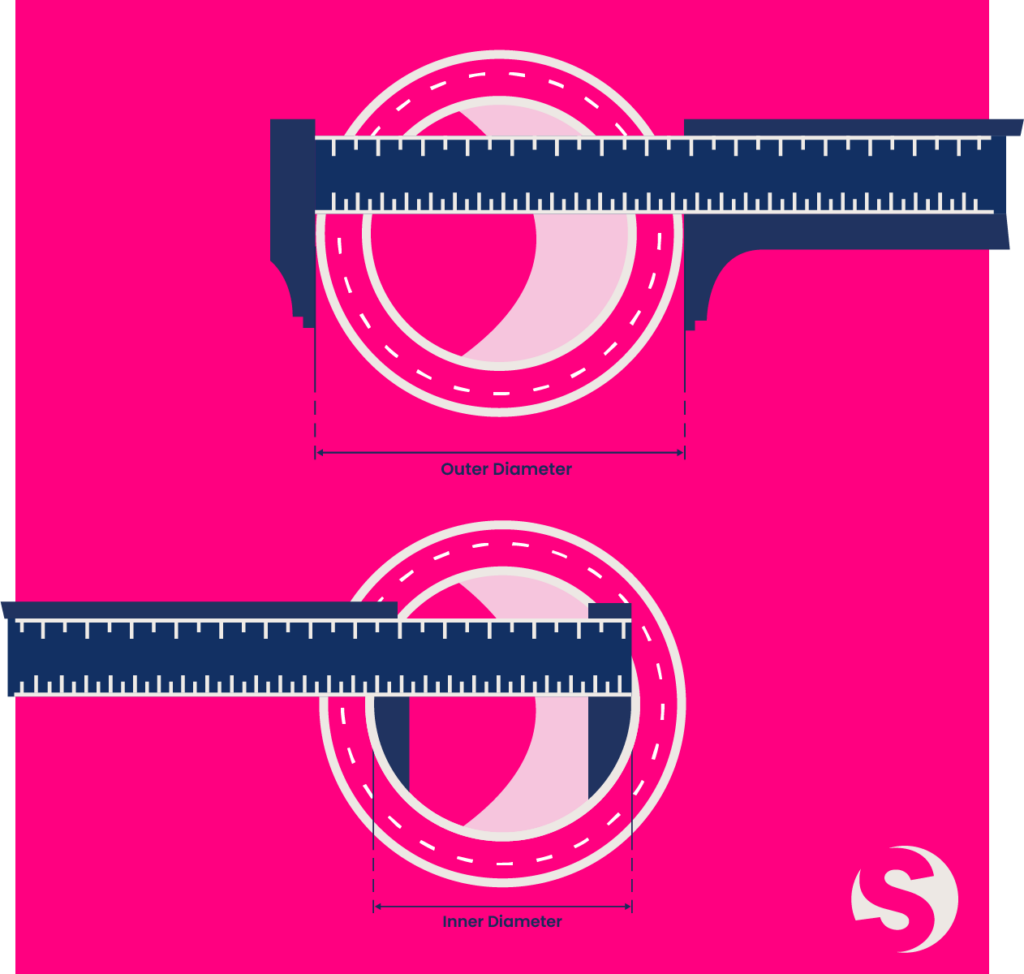

Now that you know many of the primary terms for pipe diameter and why it’s the most important measurement, here’s how you can use those terms and measure pipe diameters quickly and accurately.

Here’s what you’ll need:

- Tape measure

- Diameter measuring tool (appropriate for the size of the pipe, e.g., calliper)

Now, onto the measuring!

Step one

Start by locating a section of the pipe with a clear and accessible outer surface. If you’re measuring the outer diameter (OD), place the measuring tool or tape around the exterior of the pipe, ensuring it’s perpendicular to the pipe’s axis.

Step two

Carefully wrap the measuring tool around the pipe, ensuring it follows a straight path along the widest point. Take the measurement at a single point around the circumference of the pipe to get the most accurate OD reading.

If you’re measuring the inner diameter (ID), insert the measuring tool into the pipe until it touches the interior walls. Then, adjust it to fit snugly against the inner wall and proceed to take the measurement.

It’s as simple as that! However, it’s vital to ensure that your measurement is as accurate as possible, especially when dealing with precise applications. So if you’re unsure about the measurements, consult a professional

There you have it! Understanding pipe size terminology

So, unless you’re a professional plumber, pipe size terminology can be difficult to tackle. So don’t hesitate to use our handy guide to help you manage it!

Now that you can tell your nominal diameter from your nominal pipe size, you’re in good standing to choose the right pipes for your next home improvement project.